What you Need to Know on Temperature-Controlled Goods

A temperature-controlled product requires a specified temperature to preserve its quality. The products may be perishable goods or require a particular temperature for storage. Perishable goods include items that can spoil, decay, or become unsafe for consumption within a short time at ambient temperatures. They are usually kept under refrigeration and transported at specific temperatures with the help of temperature-controlled trucks.

Why Temperature Control is Important for Perishable Goods

Temperature-controlled food supplies require a controlled environment during transportation, e.g., frozen or chilled goods. In addition, the temperature-sensitive products usually have to be kept at a specific temperature to avoid growing bacteria, perishing, or going bad. These items may include dairy products, meat, fish and seafood, plants, medicines, and fruit and vegetables.

Most Temperature-Sensitive Food Supplies

Frozen foods like meat and dairy products need a low temperature during transit to retain their freshness when they reach the consumer. This leads to greater customer satisfaction and increased sales for the retailer. Moreover, food supplies should be delivered in the freshest possible condition, not bringing about any adverse health impact on the consumer. Some of the most temperature-sensitive food supplies include:

Wine – Heat, and wine do not mix. The good rule of thumb is the hotter you store your wine, the faster its aging process will be. However, there is a difference between quality wine and flat wine overexposed to elements. If your wine takes a long time to arrive at its destination, you better ensure it is equipped to handle the fluctuating temperatures.

Ice Cream -This one is pretty obvious. Ice cream needs to remain below freezing at all times. Ambient heat must be kept out, so the ice cream doesn’t melt. Melted ice cream overflowing in the tub has a higher chance of contamination. Re-frozen flavour has more crystallisation, so losing the original flavour is inevitable.

Fresh Fruit – Fruits are very temperature-sensitive, especially the berry types or those with thinner skins. Incorrect packaging of fruits and vegetables leads to bruising, so customers skip them, and they end up as food waste.

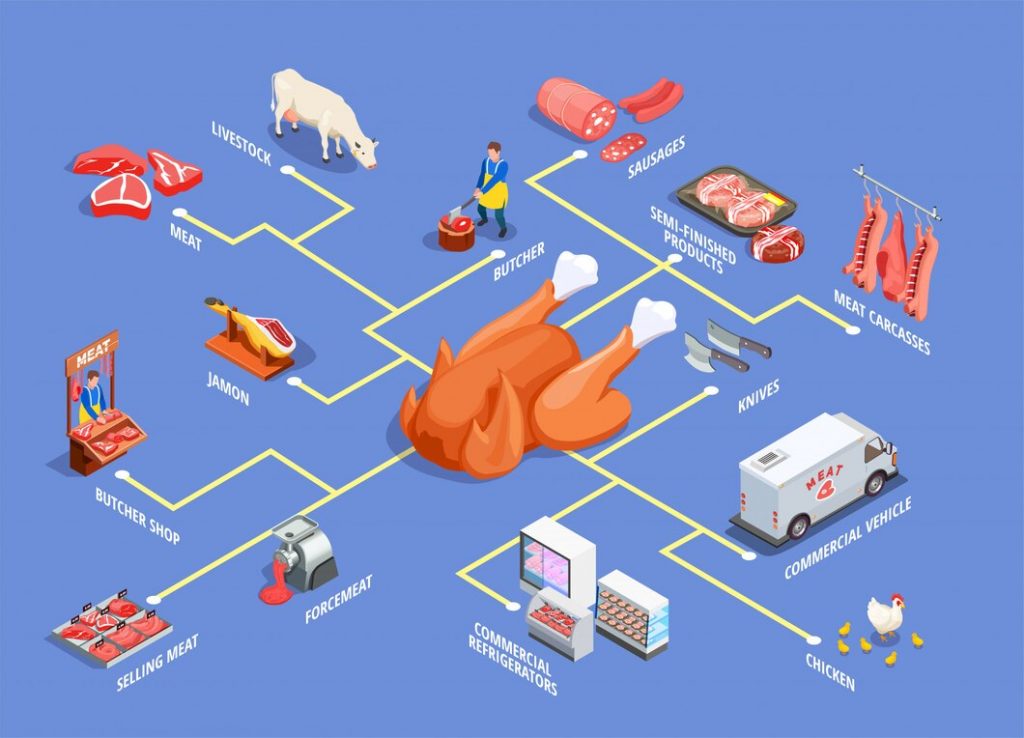

Meat – Fish, poultry, pork, and beef: these perishables should be stored at 0°C or below in transit since they can quickly go wrong if not kept in the right conditions. These supplies require consistent temperatures during their entire transportation process, from where they are produced to where they are sold and when being cooked.

How to Maintain Temperature Control

The products must be in their optimum conditions, so the temperature must remain as required throughout the entire journey. A supply chain logistics service may have to think about how they load products and if there are multimodal forms of transport needed for a trip from the place of production to the market.

When shipping temperature-controlled goods, refrigerated containers should be used. Goods must be stored in an insulated container such as a reefer (refrigerated trailer) or a temperature-controlled environment at all times, even if it’s not being carried by vehicle (e.g., in direct sunlight). Ice packs will do the job as well if a shipment is only going on a short distance journey, but this can only go so far!

What can Disrupt Temperature Control for Perishable Goods

Temperature-controlled goods and perishables present a great deal of risk in terms of loss of value or even waste. We have already established that it is vital for temperature-sensitive products to be kept at the required temperature conditions every step of the way. However, specific problems can happen along the way.

These products may be loaded in the proximity of other items that may cause a problem, i.e., heat from another product. To avoid worst-case scenarios like this, a cold chain logistics solution provider will have to create a plan for shipment and make sure the journey is set up perfectly for the product to be received. It’s the temperature control that has to be precise and the packaging. To avoid failing during transit, packaging needs to be sturdy and safe while adhering to food safety regulations. These are only considerations to ensure products arrive at their destination in sellable conditions and are safe to be consumed.

There are dozens of logistic companies, given that food manufacturers cannot hope to survive without them. If you’re still looking for a reliable logistics service provider, you might want to consider TreeLogs. With a fleet of vehicles outfitted with refrigeration systems, experienced drivers, and dedicated food-management teams, we have been delivering both quality and safety since 2018. We offer multiple options to fit your needs, so fill up our contact form to get started.